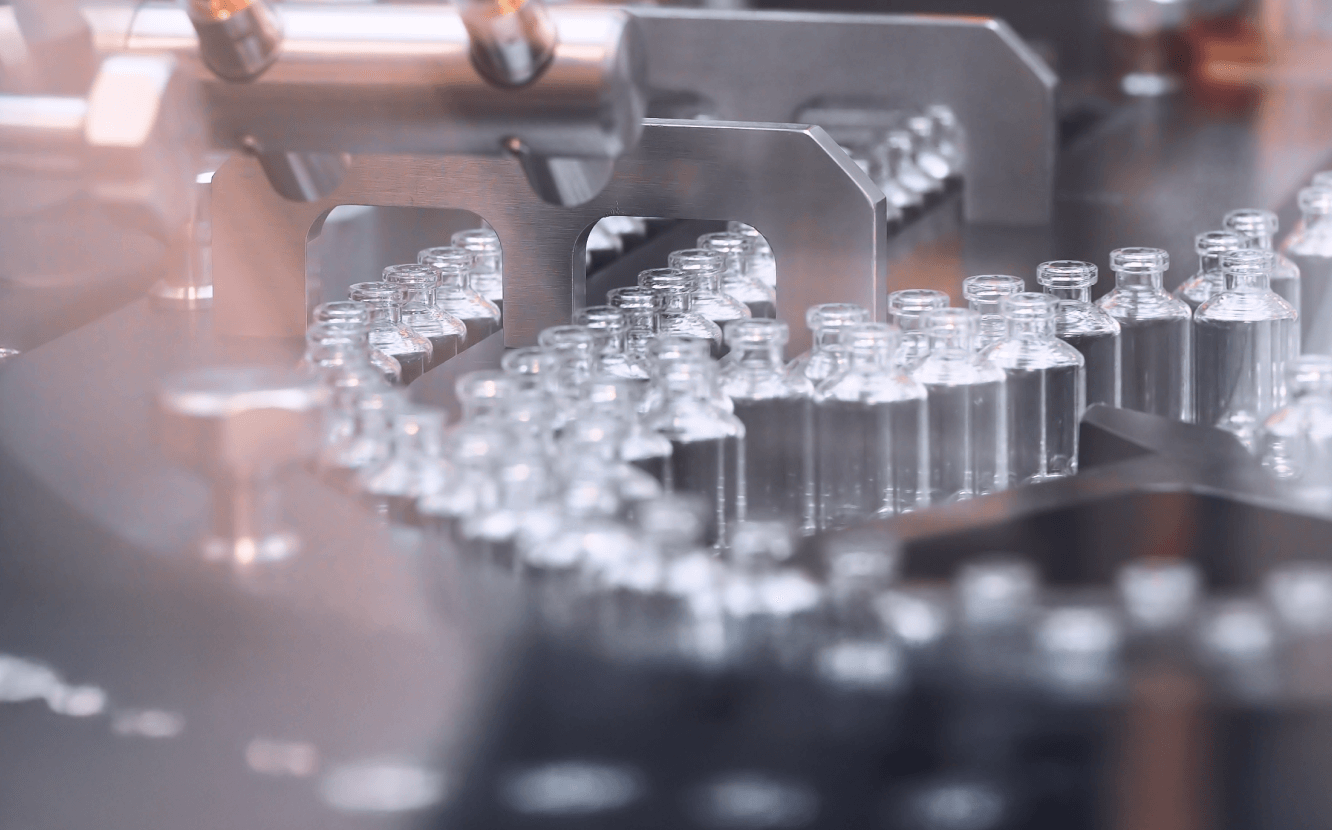

Sterile Injectables CDMO Services

US-based expertise, quality, and capacity to advance your program

ForDoz Pharma is focused exclusively on sterile drug products, helping develop and commercialize innovative therapeutics by serving as a contract development and manufacturing organization (CDMO) partner. Based in East Windsor, New Jersey, ForDoz is a fully integrated sterile drug product CDMO with end-to-end capabilities.

Advancing Sterile Drug Products

ForDoz Pharma specializes in conventional formulations and complex sterile drug products:

Conventional aqueous solution products

Lyophilized sterile formulations

Liposomal & nanoparticle-based drug delivery

Microsphere & polymer-based controlled-release systems

in situ depot formulations for long-acting injectables

Along with the ability to work with organic solvents, high-potency compounds, and small or large molecules, our expertise in conventional and complex formulations allows us to address the challenging issues that sterile drug product developers face.

ForDoz Pharma’s Services & Facilities Support the Full Product Lifecycle

Preclinical

- Pre-formulation activities

- Early-phase process development

- Toxicology dosing formulation studies

- Analytical method development

- IND-enabling formulation activities

Phase I – Phase III

- Process development & scale-up

- Clinical trial cGMP manufacturing

- ICH-compliant stability testing

- Release testing

- On-site cGMP storage

- Robust CMC and regulatory support

Commercial

- Process optimization

- Commercial cGMP manufacturing

- Release testing

- On-site cGMP storage

- Interval stability testing support

Facility

cGMP Facilities

- cGMP sterile manufacturing facility, completed FDA PAI in 2023

- In-house cGMP QC lab

- In-house cGMP microbiology lab

- On-site cGMP finished product inspection

- Packaging, labeling, serialization, and aggregation

- On-site cGMP warehouse

Working to Advance Your Conventional and Complex Injectables Program

Let us put our expertise and capacity to work to support the end-to-end needs of your conventional and complex injectable program, from early development and regulatory approval to commercial manufacturing.